Short Interval

Control (SIC)

Application

- Home

- Solve Your Challenges

- Short Interval Control (SIC) Application

Join our Talent Network

The Short Interval Control (SIC) is a structured process in which the information provided by the mining processes is periodically reviewed, making objective and quick decisions in response to them.

Value proposition of SSA Mining Solutions applying the SIC

Based on the comprehensive operational and mine planning evaluation, we will provide these solutions applying the SIC process to mine operations:

Adapt to operational changes to get as close as possible to the mine plan and to drive continuous improvement based on recorded or historical data and events to ensure operational plans are based on the fullest and most accurate understanding of the situation.

Allows operational team to identify variations with the production plan in real-time, bringing alternatives or corrective actions. These actions can be taken as soon they variations occurs.

We believe that the SIC process applied in open pit and underground mining operations guarantees an integrated approach based to programming, which includes mining planning (medium and short term) and operational activities (weekly, daily or shifts), improving efficiency, increasing productivity and maximizing the profitability of your mining business.

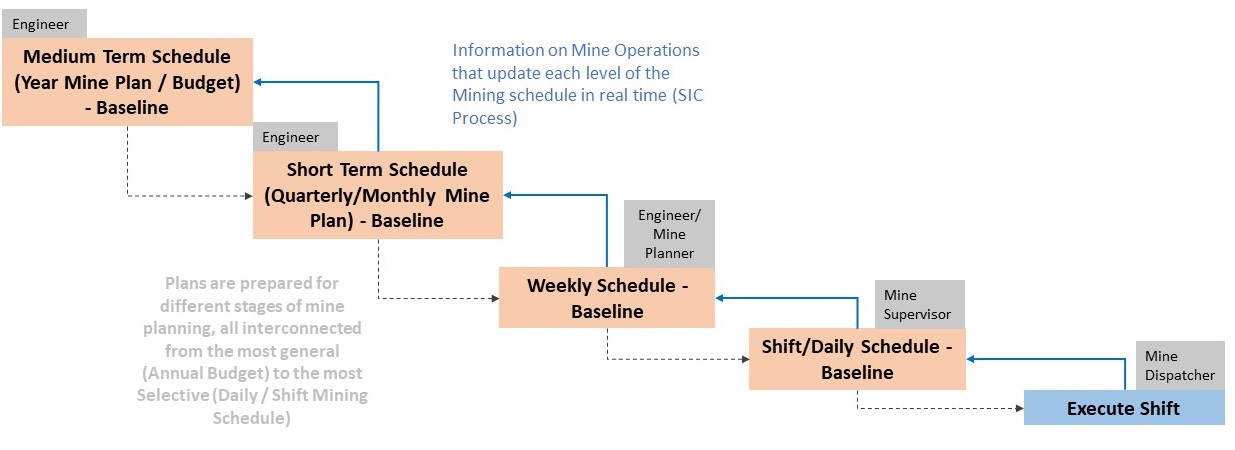

Figure. Automatic Update of Mining Schedules Applying the SIC

The Value of the Short Interval Control (SIC)

Focus on improving overall equipment effectiveness (OEE) in mining equipment and operators.

Optimizing processes in mine operations.

Reducing burdens on supervisors.

Enhancing mine safety and environmental performance.

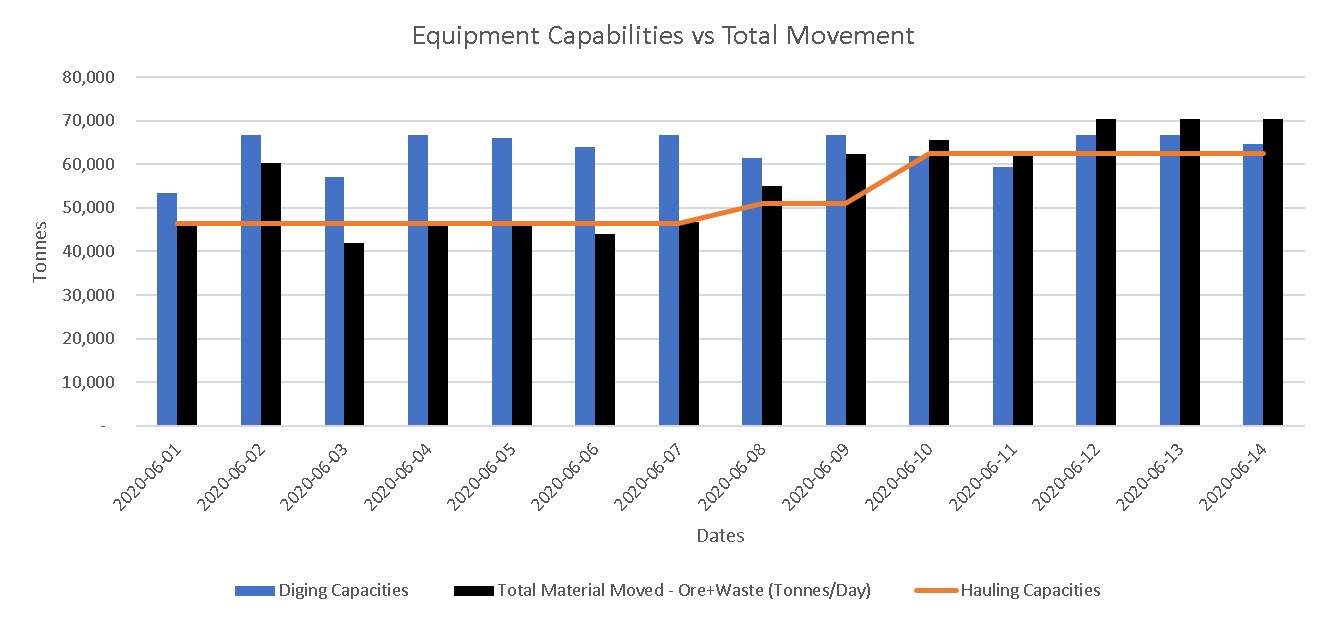

Identifying Gaps Between Mine Planning and Operations

By unifying Mine Engineering, OT and IT systems and practices in a single system architecture, businesses can identify and bridge gaps, eliminate inefficiencies, and barriers to interoperability, improve automation, accelerate innovation, optimize business processes and greatly reduce operating expenses. Enterprises can transform raw data into meaningful, actionable information that increases productivity, simplifies decision making and improves business results.

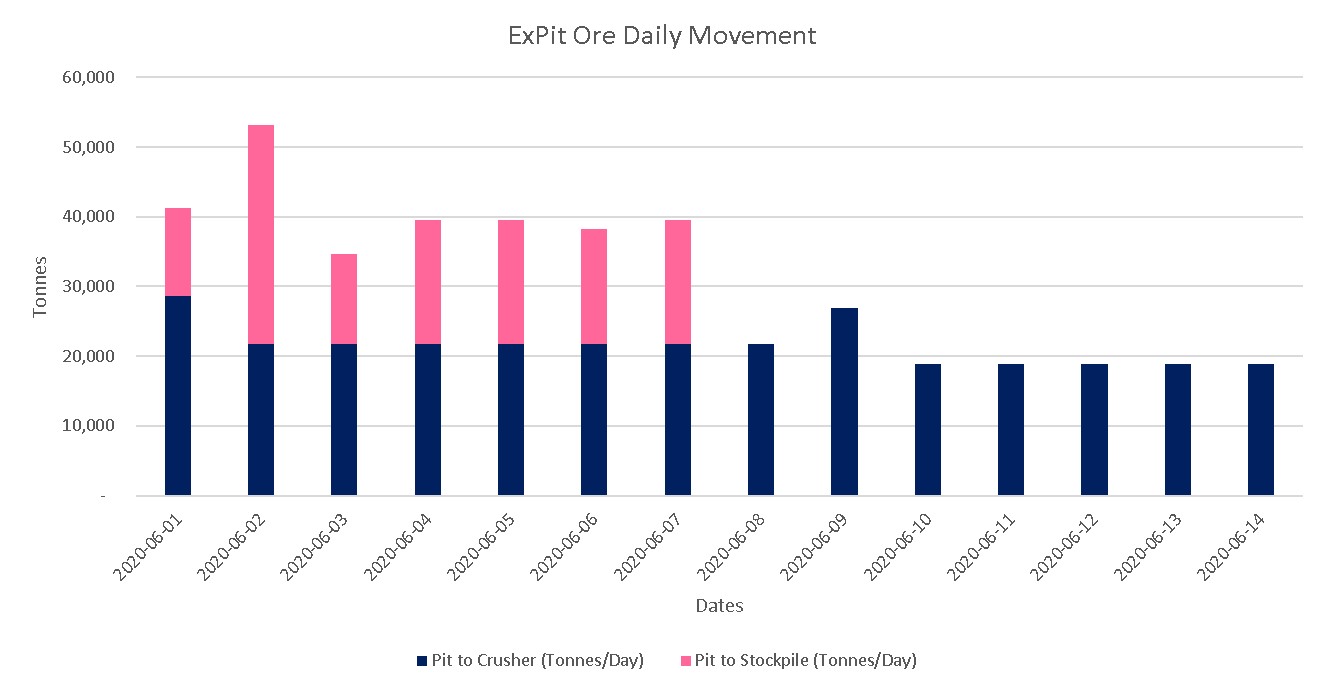

Generating Records, Reports, Charts, Dashboards and Analysis

Information technology can help mine operations locate mineral, determine operational risks and streamline mine operations. Our team identifies and analyses operational and financial performance from IT systems, to calculate and clarify losses and opportunities during operation, in addition to providing the advantage of quick decision-making in the event of any sudden operational change.

Integrated Scheduling

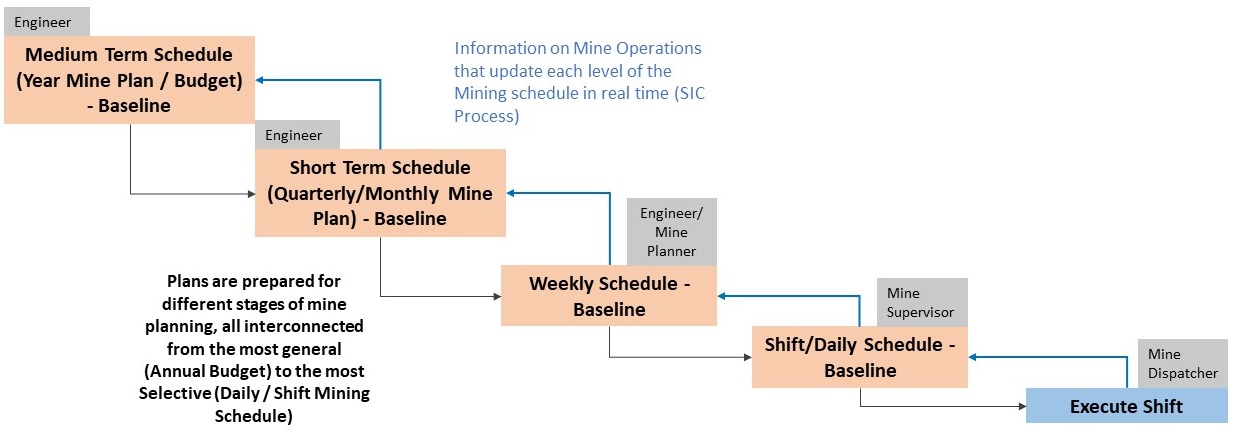

We believe that integrated scheduling is the fundamental ingredient of SIC strategies. There are many scheduling horizons to consider – from annual budget to quarterly forecast, weekly to daily/shift scheduling. All of these should be integrated by the operational system in a continuous way. The results of each daily/shift schedule should influence each new weekly schedule, and the results of each weekly schedule should influence each new quarterly forecast. Similarly, the results of each quarterly forecast should influence each annual budget.

Figure. Automatic Update of Mining Schedules Applying the SIC with Mine Planning Process.