Comprehensive

Mine Evaluation

- Home

- Solve Your Challenges

- Comprehensive Mine Evaluation

Join our Talent Network

Comprehensive Evaluation of Short and Medium Range Mine Planning System

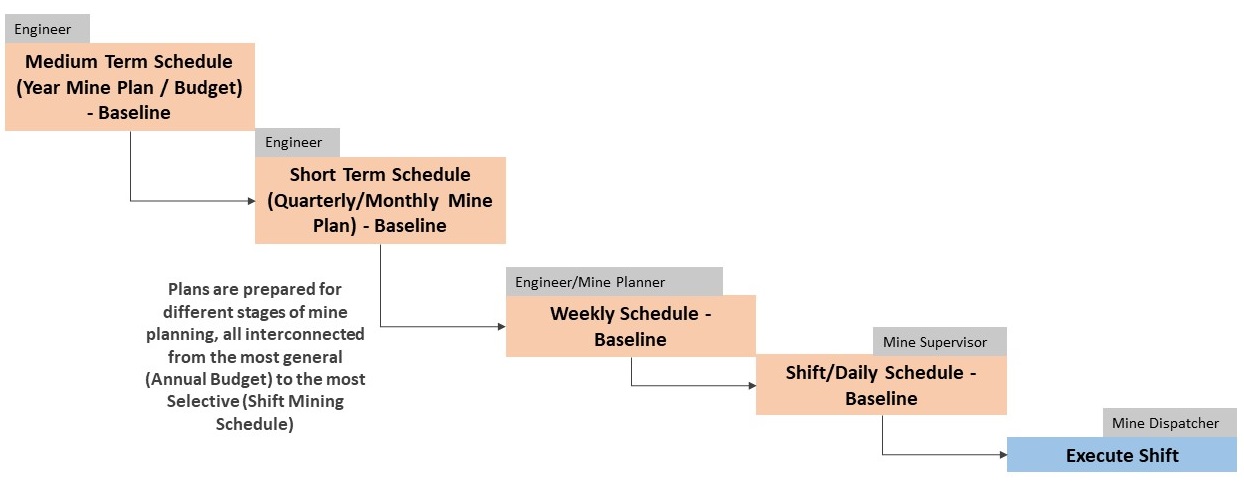

This evaluation focuses on the level of integration and the method of manual or automatic updating of each mine planning schedule given the existing operational variations.

SSA Mining Solutions staff has extensive expertise in large mine planning software and systems. Our recommendations are founded on detailed analyses and solid experience with mine planning managements. This comprehensive evaluation will additionally identify incentive opportunities that might exist for your mine planning system and help build mine planning models suitable for your organization.

Figure. Short and Medium Range Mine Planning Integration System

Comprehensive Evaluation of Mine Operations

This comprehensive evaluation is crucial before implementing the Short Interval Control (SIC) in mine operations. We need to know how the mine system captures, reports and corrects deviations, also obtaining the timeframe for these processes. The timeframe for these processes will largely depend on the level of the digital enablement in the system, integration between system, data analysis capabilities and level of automatization.

We generally focus on the Fleet Management System (FMS), analyzing its productivity, availability, uses and safety in equipment and operational personnel. During the collection and analysis of this information, operational inefficiencies can be detected; and the best decisions can be provided for the client. Our presence in the field allows us to truly understand your situation and therefore propose custom solutions that are both profitable and sustainable.

Based on the comprehensive operational evaluation, we will provide these solutions for applying the SIC:

- Adapt to operational changes to get as close as possible to the mine plan and to drive continuous improvement based on recorded or historical data and events to ensure operational plans are based on the fullest and most accurate understanding of the situation.

- Allows operational team to identify variations with the production plan in real-time, bringing alternatives or corrective actions. These actions can be taken as soon they variations occurs.

KPI’s Analysis for Mining Equipment

As all mine planners for open pit and underground mines, one of the biggest challenges in your day-to-day job is not getting the mine plan written down, it’s the adherence of other operational departments to the plan. A keyway to get other departments stick to a mine plan is to develop KPIs for the departments that are credible, achievable and still push them to over-deliver.

Through the SIC, SSA Mining Solutions apply the concept of a ‘dynamic’ KPI system to mining equipment. Regularly monitoring, reviewing, evaluating and updating KPIs is a safe way to ensure they are always realistic, and (top end) achievable, keeping staff motivated and engaged.

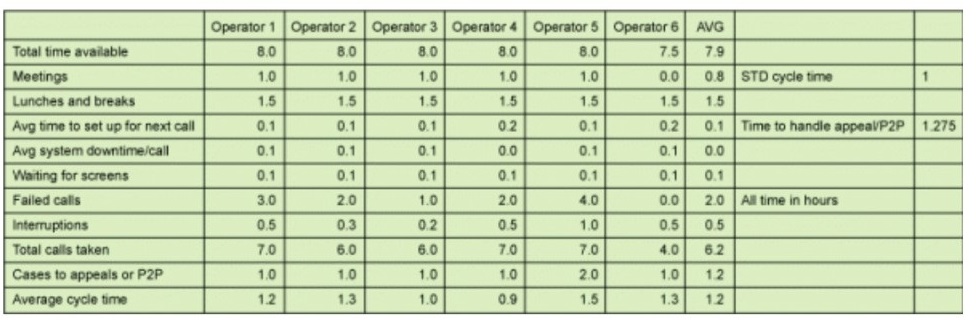

Figure. Continuous evaluations for equipment operators.

KPI’s Analysis for Mining Equipment - Utilization

This element of mine operational assessment intensively analyzes mine equipment downtime during daily operations.

The redesign of the processes, better management of human resources and equipment, reduces operational times and provides the opportunity to increase production without investing additional capital or available resources.

Operator Performance Variability Analysis

Through the acquisition and analysis of data provided by the fleet management system and constant field observation, our staff assesses the performance of each mine equipment operator, minimizing production variability between operators and increasing the overall productivity of your fleet.